How Innovations in Metal Fabrication Changed My Business in Ohio (2025 Update)

Ever had that moment where your industry suddenly jumps ahead, and you're barely hanging on? 🏒 Well, in early 2025, that's exactly how I felt. My metal fabrication workshop right outside Columbus, Ohio-specializing in CNC machining and welding services-went through one heck of a transformation. If your business relies on industrial manufacturing or structural steel like mine, trust me, read to the end. There's a few innovations in sheet metal fabrication I learned about (painfully!), and maybe they'll save your shop from scrambling around the way mine did.

How I Got Smacked by Unexpected Innovation

So, picture this-it's mid-February 2025, and orders are coming in strong. I'm running the classic Haas CNC machines I've had forever, trusty but sorta sluggish compared to the competition popping up here in Ohio. Then one afternoon, I lose a big welding job to, of all things, a small competitor using automated laser welding. Man, laser welding? Since when is that accessible around here?

Feeling pretty salty-but honestly worried-I got curious. How exactly were my competitors so agile and fast? Turned out, while I was comfortable with my old-school ways, everyone around me was quietly upgrading their metal fabrication approach. Automation, laser tech, software-driven quality checks… kinda wild, right?

Anyway, I had to catch up or risk losing everything I'd worked toward.

Real-Life Game Changers in Metal Fabrication I Experienced

After digging around online, visiting tradeshows, and shamelessly spying (I mean, researching!) on competitors, I jumped headfirst into upgrades. 🎉 Here's what stood out dramatically for me since mid-2025:

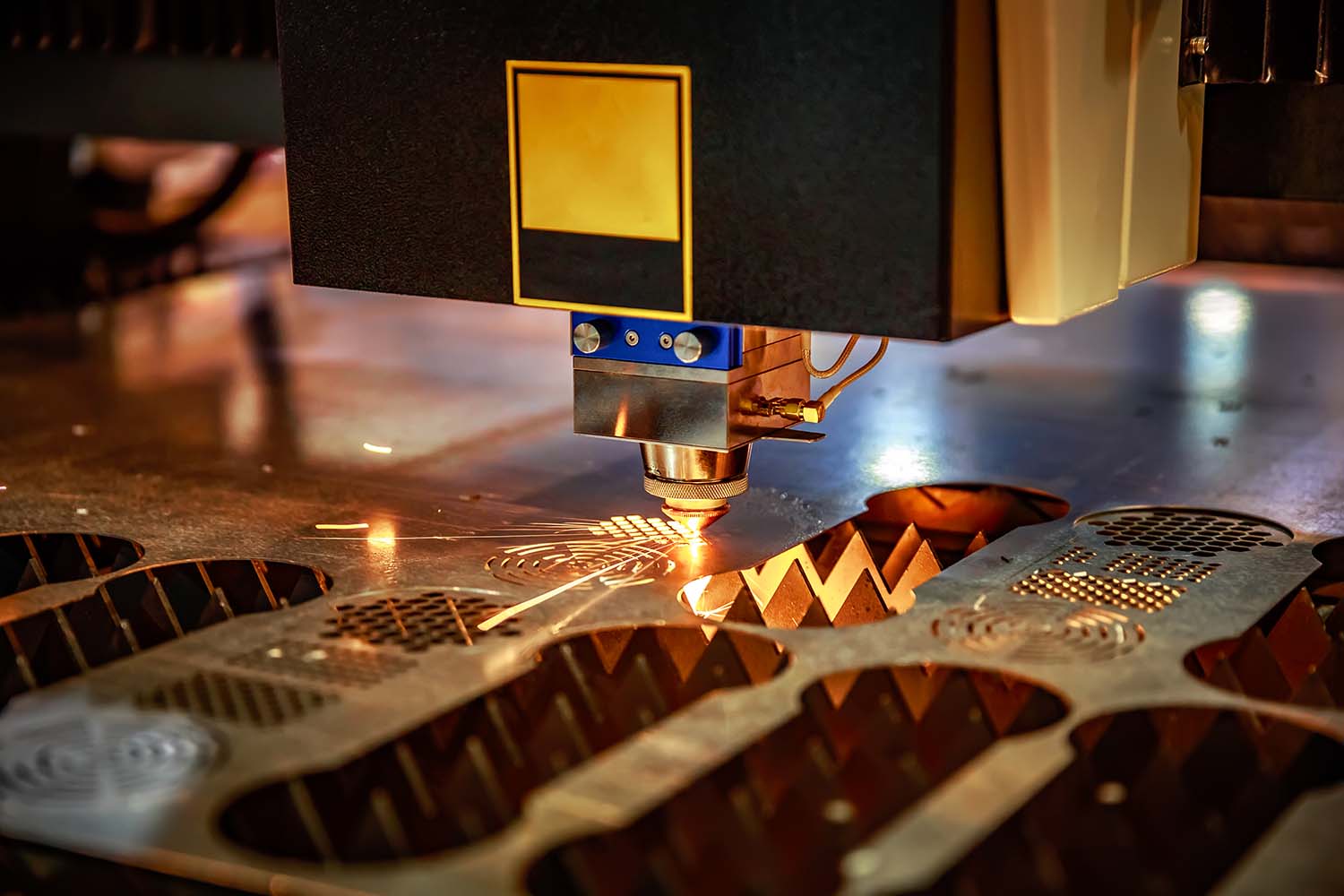

Automated Laser Welding - Ohio's Hidden Gem?

Not gonna lie, the automated laser welding station I installed in May 2025-a Trumpf TruLaser Weld 1000-blew me away from day one. Welding sheet metal parts for fittings and structural steel components used to take ages, and now my guys zipped through jobs like nothing.

Thought hiccup: I hesitated big-time over the initial price tag. Investment was steep enough to pretty much ruin my sleep schedule for a month. (My bank account still hasn't forgiven me.) But holy smokes, the productivity gains literally tripled the throughput.

CNC Machining Meets AI Software

AI-driven software integrations? Seemed kinda sci-fi, but by mid-2025, providers like Autodesk Fusion 360 and Mastercam had some pretty slick AI-powered predictive machining modules.

I bit the bullet in June and gave Autodesk Fusion a shot. Simulation-driven prediction reduced our tool wear significantly. Less tool breakage? More uptime, less downtime. Who'd have thought, AI+ machining = less yelling at broken bits?

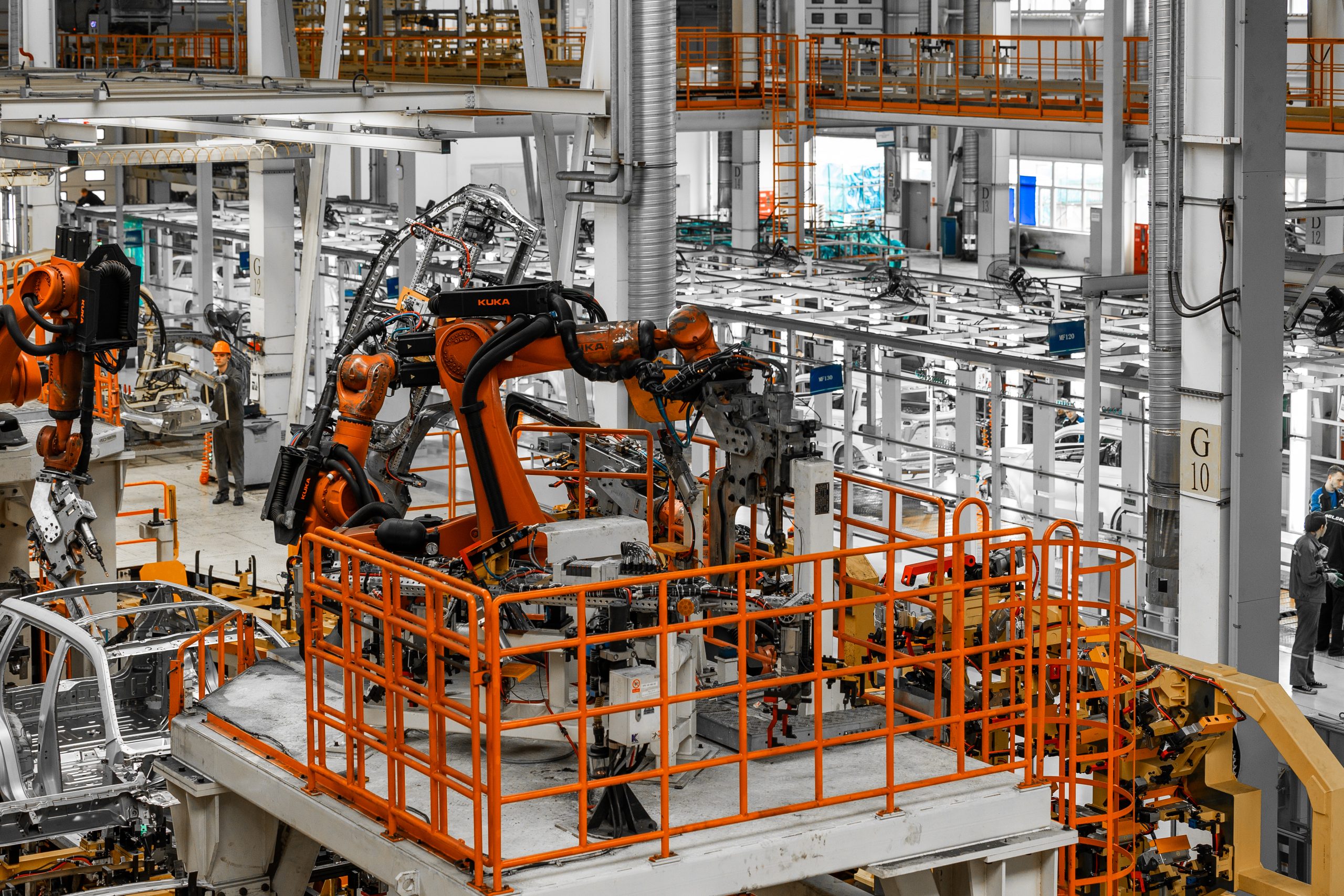

The Robotic Sidekick Revolution

Back in September 2025, I went all-in on a collaborative robot-specifically bought a UR10e from Universal Robots. At first, employees grumbled, thinking robots would take jobs. I won't lie, that concern hit me too.

But actually? It let my team offload repetitive tasks like handling sheet metal blanks and minor billet loading. They had more time for tasks needing creativity and experience. Ironically, the team ended up loving "Robbie" (yep, that's its nickname) because they went home far less exhausted.

List of Honest Mistakes I Made Upgrading My Fabrication Shop

I learned this the hard way…maybe you'll avoid some headaches: 👍

- Ignoring Employee Training - thinking the technology will fix everything without thoughtful hands-on training was a real blunder.

- Choosing Cheap Initially - My first attempt at automation was a cheap robotic arm on eBay. You don't wanna know how that went (Spoiler: It didn't move much).

- Underestimating Maintenance Costs - newer tech brings unexpected expenses. Upgrade carefully.

The Great Metal Fabrication Shootout of 2025 (In My Humble Opinion…)

Okay, let's put things into perspective. Here's my homemade-to-the-rescue table comparing those upgrades I went through:

| Technology | Initial Cost 💸 | Learning Curve 📚 | Productivity 🏋️ | Best benefit 🌟 |

|---|---|---|---|---|

| Automated Laser Welding | Pretty high | Medium | Sky-high | Speed & Weld Quality |

| CNC AI Software | Moderate | Low | Solid increase | Less downtime |

| Collaborative Robots | High-ish | Medium-high | Major boost | Employee morale |

What Experts Say on Metal Fabrication Innovations

According to the 2025 Manufacturing Trends Report by Deloitte, "By embracing automation, artificial intelligence, and robotics technologies, fabrication shops can expect to achieve productivity gains upwards of 45%." [Source: Deloitte, 2025 Manufacturing Industry Outlook]

And James Carter, professor and researcher at The Ohio State University's Center for Advanced Manufacturing, confirmed: "Shops using automated laser welding and AI-driven CNC processes consistently outperform their peers in Ohio and nationwide." (OSU Center for Advanced Manufacturing, 2025).

Some Real FAQs I Get from Fellow Shop Owners

How much did automated laser welding end up costing you total?

Honestly? Dropped around 200 grand after install & training in May, 2025-made my accountant weep. Worth it? Absolutely.

Can robots really replace skilled labor completely?

Nah, man. The robots handle the grunt work. Your skilled welders and machinists still own the crafty stuff. (Trust me on that.)

Is AI-driven CNC machining complicated for seasoned workers?

Depends on your workers really. Not too bad with the newer softwares out as of late-2025. Took my team a couple weeks of initial grumbling.

So Here's My Take After A Wild 2025 in Metal Fabrication…

Feeling left behind sucks. Period. If you're hesitating about upgrading, getting into innovation like automated laser welding, or even considering CNC machining with software integrations as I was, just do it. Yes, it's expensive and stressful. Yes, it's intimidating at first. And yes, there's mistakes waiting to laugh at you along the way.

But here's the thing-the future of industrial manufacturing and structural steel processing isn't slowing down. Ohio, frankly, is only getting more competitive. For me, biting the bullet this year literally saved my business. Maybe you'll say I'm being dramatic, but that's honestly how it felt.

Can I promise you'll have the same exact success? Nope, I really can't. Manufacturing's tricky and everyone's shop is a unique snowflake (ha!). But if you're anything like me, staying comfortable is dangerous. Stay curious, take calculated risks, and don't get left in the dust by innovation's relentless wave.

Quick disclaimer: We are an independent, scrappy group of shop owners and industry nerds with no connections to any previous writers or domain owners-we're just sharing what worked (and failed) from our firsthand experience.